The Beverage Industry

Lifting Equipment for the Beverage Industry

In the beverage industry, handling heavy items like kegs, bottles, and cartons is a daily task that requires efficient and safe solutions. Material Handling Solutions (MHS) offers a wide range of lifting equipment tailored for the beverage industry, including pallet lifting equipment, vacuum lifting equipment, keg rotators, and gravity conveyors, all designed to enhance operational efficiency and reduce the risk of musculoskeletal disorders (MSDs).

Pallet Lifting Equipment - Streamlining Bulk Handling

Pallet lifting equipment is essential in the beverage industry for moving and transporting heavy loads such as cartons and pallets. MHS provides robust pallet jacks, pallet trucks, and pallet rotators that facilitate easy and safe handling of these bulky items, significantly reducing physical strain on workers.

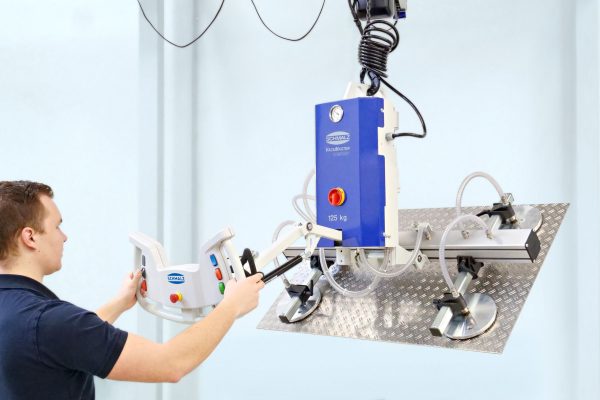

Vacuum Lifting Equipment - Ensuring Delicate Handling

Vacuum lifting equipment, offered by MHS, is ideal for safely lifting and moving heavy and delicate items like kegs and bottles. These systems use suction to securely grip and transport items, minimizing manual handling and reducing the risk of injury and product damage.

Keg Rotators - Simplifying Keg Handling

Keg rotators are a specialized solution in the beverage industry for safely lifting and rotating heavy kegs. Attached to vacuum lifters, MHS’s keg rotators allow workers to easily and safely maneuver kegs, reducing the risk of strains and sprains associated with manual handling.

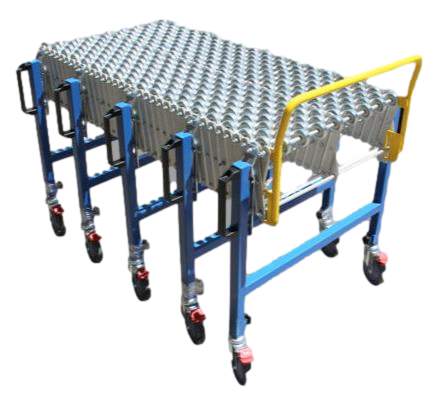

Gravity Conveyors - Effortless Product Movement

Gravity conveyors are an efficient way to move products through the production line. MHS provides gravity conveyors that use unpowered rollers, allowing products to move with minimal effort and reducing the physical demands on workers, thus lowering the risk of injuries.

Enhancing Worker Safety and Reducing Injury Risks

MHS’s lifting equipment for the beverage industry focuses on enhancing worker safety and reducing the risk of MSDs. By providing ergonomic lifting solutions, we help to create a safer working environment, preventing muscle strain and fatigue among employees.

Boosting Productivity in Beverage Operations

Incorporating MHS’s advanced lifting equipment can significantly boost productivity in the beverage industry. These solutions help reduce handling time and effort, allowing workers to focus on other critical tasks, thereby increasing overall operational efficiency.